Centrego Marine

Applications

Extremely effective

Disinfection of production areas

The solution has proven extremely effective both for cleaning and disinfection of the production area. Practically it can shorten the wash process and in some cases eliminate some of the steps involved.

The solution has been approved by the Danish Food Authorities for disinfection without the mandatory rinsing afterward.

If you apply this in the cleaning water below 400 ppm you can change the traditional 5-steps cleaning (rinse, soap, rinse, disinfection and rinse) process to 3-steps cleaning (rinse-soap-disinfection) process. To the soap step you simply add foam enhancer. The disinfection step takes care of the rinsing away the foam enhancer and after the 3rd step the production area is ready for inspection.

Personal safety is also dramatically increased with application of this solution. To not use chemical protection gear is actually encouraged.

Disinfection of process water

Applying the solution into the main water supply to the factory (land based or on a vessel) renders stopping of production almost superfluous in regards to the periodical cleaning due to safety reason – food saftey and personal safety alike. Practical test show that surface are much cleaner and therefore less slippery than before the application. This results also in way lower bacterial counts on al surface the process water comes in contact with. This can be applied both in saline water and fresh water. Customers experience higher yield and higher througput because of lesser needs for stopping the production.

Disinfection of fish holding tanks

In regards to fish holding tanks the effect is talked about in two steps. Adding the solutions in high concentration for cleaning purposes of the empty tanks and secondly adding the solution in a relatively low concentration for adding shelf life to the fish in the tanks.

Practical tests show increased shelf life, lower TVBN-value, lower bacterial load and lower levels of histamine.

Tests done on whole carcass blue whiting also show very good organoleptic results: Quality of the eyes, gills and firmness of the fish.

Laundry machines

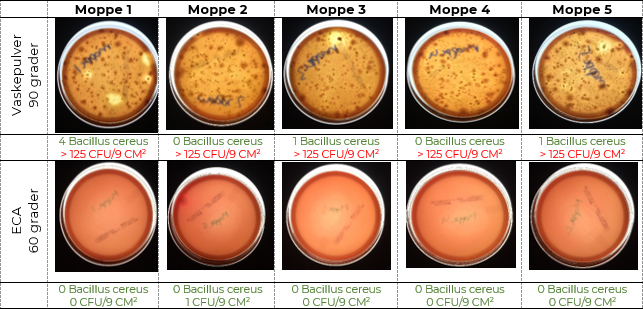

It is well known that most laundry machines do not reach the target temperature, so a 90-degree wash does not guarantee that the clothes are microbiological clean. By replacing laundry detergent with ECA (MOW) to the laundry machine, we not only wash the clothes clean, but also disinfect the clothes so they do not contaminate the products.

Studies show that most laundry machines start breaking down within the first four years and one of the most common causes is soap residues, with ECA wash this does not happen and laundry machines will last longer and need fewer services when washing with ECA.

Below is the results of laundered mops washed at 90 degrees and with ECA at 60 degrees.

Laundry detergent is responsible for 4% of every person COD impact on the environment, by using ECA as laundry detergent, you will make a Green and sustainable choice and the fact that you can lower the washing temperature from 90 to 60 degrees typically reduces the power consumption with up to 70% and thereby you save money by doing something good for the environment,